Sliding Vertical Injection Molding Machine Supplier

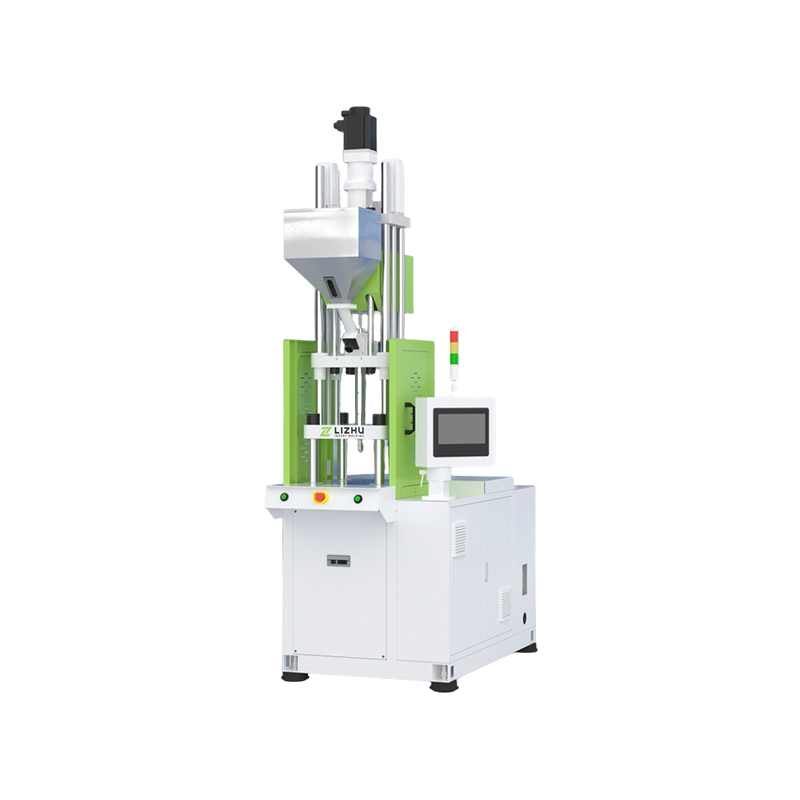

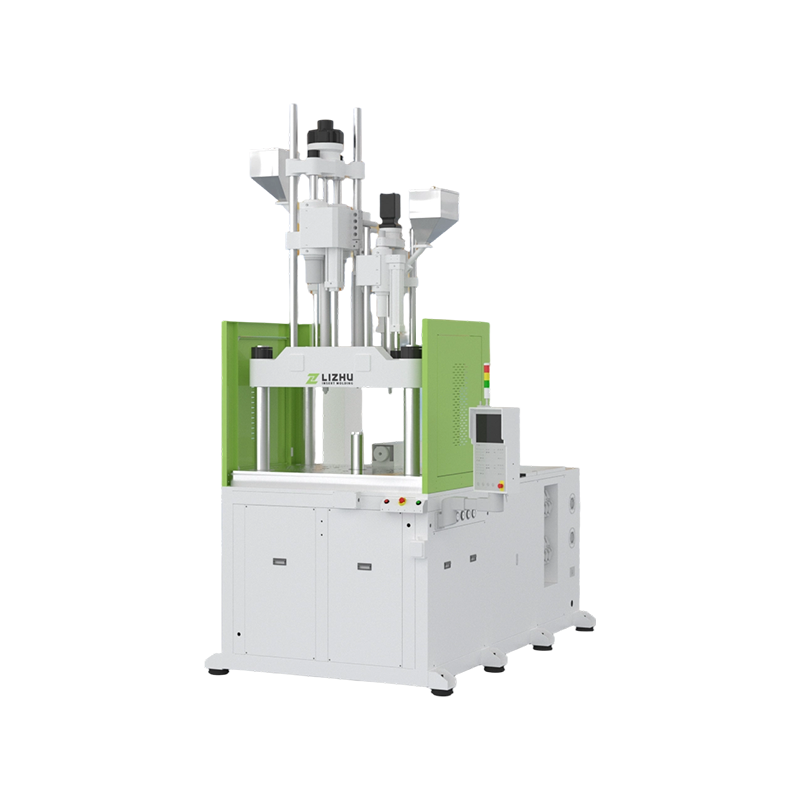

The sliding vertical injection molding machine is a high-efficiency injection molding equipment developed from the traditional vertical injection molding machine. It comes in single-slide and double-slide types. The mold opening and closing is achieved by the movement of the slide plates.

Features:

The mold operates on a fixed slide plate, resulting in a simple structure and intuitive operation.

It has a small footprint, is flexible in operation, and is suitable for various insert molding needs.

It can be equipped with a robotic arm to achieve basic automated part handling and loading/unloading.

The large exposed mold area provides ample working space, making it ideal for use with robotic arms and automated loading/unloading equipment.

The stable operating cycle facilitates the automation transformation of insert molding.

It is particularly suitable for medium to large-volume production and scenarios with high automation requirements.

-

What Makes Sliding Vertical Injection Molding Machines Stand Out in Precision and Speed?Introduction to Sliding Vertical Injection Molding Machines As manufacturing processes continue to evolve, the demand for more efficient, precise, and versatile machinery has led t...

-

Why Should You Choose a Vertical Injection Molding Machine for Your Production?Introduction to Vertical Injection Molding Machines A vertical injection molding machine is an advanced manufacturing tool used to create plastic components by injecting molten pla...

-

Why Are Precision Injection Molding Machines Essential for Modern Manufacturing?Introduction to Precision Injection Molding Machines Precision injection molding machines represent one of the most critical innovations in modern manufacturing. These machines pla...

-

From Manual Loading to Full Automation: The Upgrade of Vertical Injection Molding Production LinesSuzhou LIZHU Machine has long served injection molding industry clients, witnessing and driving the evolution of vertical injection molding production lines from manual loading to ...

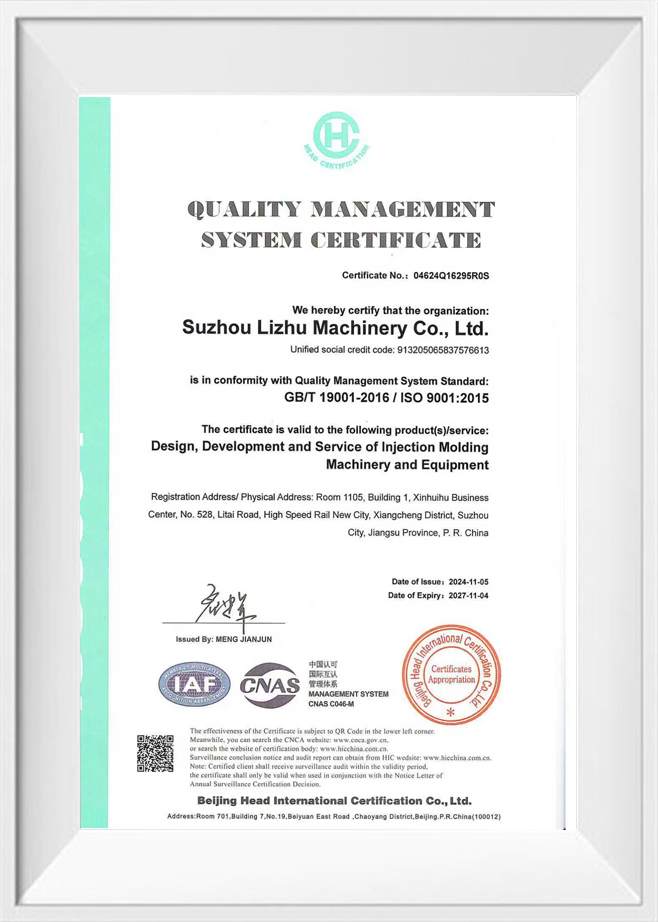

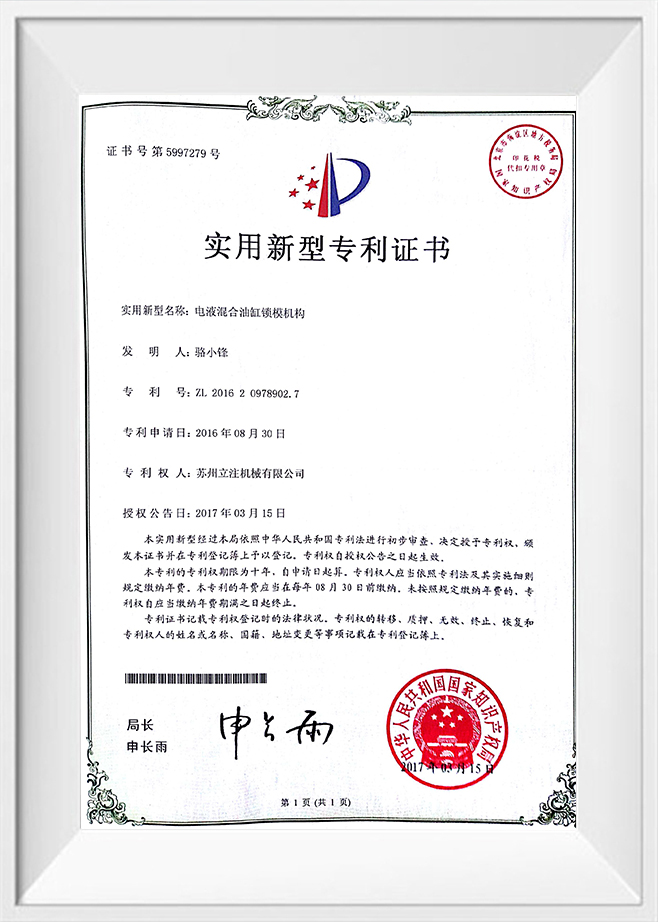

Sliding Vertical Injection Molding Machine is designed for high-speed, precision injection molding, offering a versatile solution for producing complex molded parts across a wide range of industries. These machines are recognized for their ability to efficiently handle multi-component molding processes, providing superior precision, faster cycle times, and excellent repeatability. Used extensively in automotive, medical, electronics, and aerospace applications, these machines ensure consistent part quality and productivity. LIZHU Machinery Co., Ltd. specializes in the design and manufacturing of these advanced machines, leveraging cutting-edge technology to meet the evolving demands of global industries.

Core Features and Benefits

-

High-Speed Performance: The Sliding Vertical Injection Molding Machine excels in producing high volumes of high-quality components with rapid cycle times, improving operational efficiency. At LIZHU, we integrate advanced precision technology to ensure that every cycle achieves exceptional quality.

-

Multi-Component Molding: These machines can handle multi-color and multi-material injection processes, ideal for complex parts that require multiple materials or colors. Our machines are engineered to meet these diverse needs, supported by our ongoing innovation in molding solutions.

-

Space-Saving Design: The vertical structure of the machine optimizes space utilization, particularly in environments where floor space is limited.

-

Precision and Reliability: Thanks to our commitment to innovation, LIZHU ensures that every Sliding Vertical Injection Molding Machine incorporates the latest advancements in control systems, allowing for precise, reliable, and repeatable molding processes.

How It Works

The machine operates by injecting molten material into a mold cavity through a vertical injection process. The sliding mechanism allows the mold to open and close efficiently while enabling quick changes between different molds for multiple components. This design improves operational flexibility, ensuring faster and more accurate molding cycles. LIZHU integrates advanced control systems into each machine, enhancing user experience and optimizing productivity.

Applications

The Sliding Vertical Injection Molding Machine is widely used across multiple industries, including:

-

Automotive: Producing parts such as connectors, housings, and trim components. At LIZHU, we understand the high precision required for automotive applications and offer solutions tailored to meet those needs.

-

Electronics: Manufacturing precise parts for consumer electronics like mobile phone components, connectors, and housings.

-

Medical: Fabricating medical device components that require high standards of cleanliness and precision.

-

Aerospace: Creating lightweight, high-strength components for aircraft and satellite systems, where material integrity is crucial.

Maintenance Guidance

To ensure optimal performance and longevity, regular maintenance practices for the Sliding Vertical Injection Molding Machine include:

-

Cleaning the Mold and Injection Unit: Regular cleaning is essential to prevent material buildup and maintain smooth operation. At LIZHU, we provide detailed guidelines for proper cleaning to help maximize machine lifespan.

-

Checking for Wear and Tear: Routine inspection of critical components such as the injection unit, hydraulic system, and electrical components helps identify potential issues early.

-

Lubrication: Proper lubrication of moving parts, including the sliding mechanism, reduces friction and wear, ensuring consistent performance.

Comparison with Other Injection Molding Machines

Compared to horizontal injection molding machines, the Sliding Vertical Injection Molding Machine offers significant advantages, such as improved space efficiency and the ability to handle multi-component molding with reduced cycle times. LIZHU’s machines are designed with these advantages in mind, ensuring both flexibility and high productivity in manufacturing environments.

FAQs

-

What materials can the Sliding Vertical Injection Molding Machine handle?

These machines can process a variety of materials, including thermoplastics, elastomers, and BMC, offering flexibility for diverse applications. LIZHU machines are engineered for precise material handling to meet the unique needs of each industry. -

Can the machine produce multi-color parts?

Yes, the Sliding Vertical Injection Molding Machine is capable of multi-color molding, which is ideal for products requiring different colors or materials. LIZHU has specialized in creating machines capable of handling these complex processes. -

What industries benefit most from this machine?

Industries such as automotive, electronics, aerospace, and medical equipment manufacturing benefit greatly from the Sliding Vertical Injection Molding Machine due to its high precision and multi-component molding capability, supported by LIZHU’s innovation in injection molding technology.

中文简体

中文简体