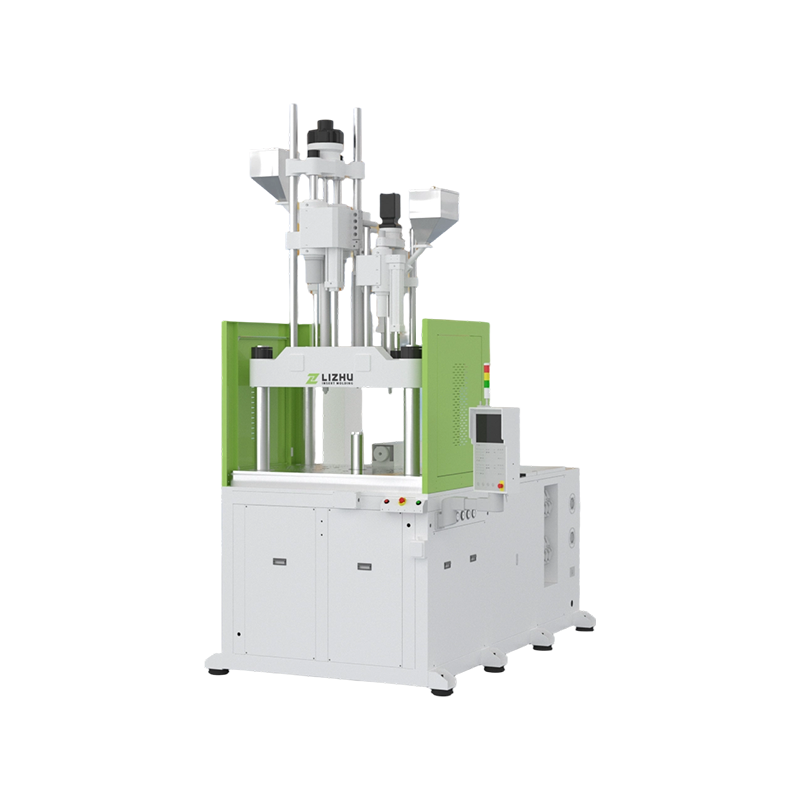

Vertical injection molding machine Manufacturers

Vertical clamping and injection molding machines, driven by servo motors, feature efficient closed-loop control, stable repeatability, and significantly improved product yield.

The machines offer a wide range of injection weights, with clamping forces ranging from 40 tons to 1000 tons, suitable for various precision machining needs.

The company also provides various optional configurations, such as high-speed injection systems and servo energy-saving systems, to meet the production needs of different customers.

Vertical injection molding machines are injection molding equipment that vertically mounts the injection unit and mold. They offer advantages such as space saving, easy automation, high-precision control, suitability for precision machining and multi-cavity mold production, and are widely used in precision electronics, automotive, medical, and other fields.

-

What Makes Sliding Vertical Injection Molding Machines Stand Out in Precision and Speed?Introduction to Sliding Vertical Injection Molding Machines As manufacturing processes continue to evolve, the demand for more efficient, precise, and versatile machinery has led t...

-

Why Should You Choose a Vertical Injection Molding Machine for Your Production?Introduction to Vertical Injection Molding Machines A vertical injection molding machine is an advanced manufacturing tool used to create plastic components by injecting molten pla...

-

Why Are Precision Injection Molding Machines Essential for Modern Manufacturing?Introduction to Precision Injection Molding Machines Precision injection molding machines represent one of the most critical innovations in modern manufacturing. These machines pla...

-

From Manual Loading to Full Automation: The Upgrade of Vertical Injection Molding Production LinesSuzhou LIZHU Machine has long served injection molding industry clients, witnessing and driving the evolution of vertical injection molding production lines from manual loading to ...

Vertical injection molding machines are essential for precision manufacturing across a variety of industries, including electronics, automotive, aerospace, medical, and semiconductor packaging. These machines are designed to efficiently mold plastic, silicone, BMC, and metallurgical powders with high accuracy. Unlike traditional horizontal machines, vertical injection molding machines utilize a vertical mold setup, providing distinct advantages in terms of space-saving, mold handling, and the ability to incorporate insert molding for more complex parts.

Core Functionality and Performance

The primary function of vertical injection molding machines is to inject molten material into a mold cavity under controlled conditions to produce highly detailed, durable components. Their vertical orientation allows for better gravity assistance during the injection process, improving the efficiency of material flow and reducing the chances of defects. These machines also facilitate multi-color and multi-material molding, enhancing their versatility in meeting diverse production needs.

The core performance highlights of vertical injection molding machines include:

-

Space Optimization: Vertical designs save floor space and make it easier to handle larger molds.

-

High Precision: Capable of producing components with tight tolerances, ideal for applications requiring high accuracy.

-

Efficiency in Multi-Component Molding: Excellent for multi-material or insert molding, especially in industries such as automotive and electronics.

Applications and Case Studies

Vertical injection molding machines find applications in a range of industries:

-

Automotive: Used for molding intricate parts like connectors, bushings, and seals, which require precision and strength.

-

Medical: Ideal for manufacturing small, complex components like syringe parts, handles, and connectors, where hygiene and precision are paramount.

-

Electronics: Commonly employed for producing parts like connectors and housings, which need to meet strict dimensional and performance standards.

Detailed Comparison

When comparing vertical injection molding machines to their horizontal counterparts, several factors come into play:

-

Space Efficiency: Vertical machines require less floor space, making them suitable for environments with limited room for larger equipment.

-

Multi-Component Molding: Vertical machines are particularly suited for multi-component or insert molding due to their ability to handle complex mold setups more easily.

-

Maintenance: Vertical machines typically have fewer parts in motion, which can reduce wear and tear, translating to lower maintenance costs over time.

In contrast, horizontal machines often excel in higher-volume production environments, where speed and straightforward operation are key. However, for more complex molds and intricate parts, vertical injection molding machines offer superior performance.

Maintenance Tips and Best Practices

Maintaining vertical injection molding machines requires a focus on several key areas:

-

Regular Cleaning: Ensure molds are cleaned and inspected for wear after each production cycle.

-

Lubrication: Keep moving parts properly lubricated to reduce friction and extend machine lifespan.

-

Check for Leaks: Periodically check hydraulic systems and seals to prevent material leakage, which can affect production quality.

By adhering to these practices, manufacturers can ensure optimal performance and longevity of their vertical injection molding machines.

FAQs

Q: What are the main advantages of using a vertical injection molding machine?

A: Vertical machines save floor space, offer high precision, and are ideal for multi-material molding, especially in applications like automotive and electronics.

Q: Can vertical injection molding machines handle high-volume production?

A: While they excel in precision and complexity, vertical machines are also capable of handling high-volume production, particularly when efficiency is required in multi-component molding.

Q: What industries benefit most from vertical injection molding machines?

A: Vertical injection molding machines are widely used in automotive, medical, electronics, and aerospace industries, where precision and multi-material molding are crucial.

中文简体

中文简体