Vertical Hydraulic Press Manufacturers

-

What Makes Sliding Vertical Injection Molding Machines Stand Out in Precision and Speed?Introduction to Sliding Vertical Injection Molding Machines As manufacturing processes continue to evolve, the demand for more efficient, precise, and versatile machinery has led t...

-

Why Should You Choose a Vertical Injection Molding Machine for Your Production?Introduction to Vertical Injection Molding Machines A vertical injection molding machine is an advanced manufacturing tool used to create plastic components by injecting molten pla...

-

Why Are Precision Injection Molding Machines Essential for Modern Manufacturing?Introduction to Precision Injection Molding Machines Precision injection molding machines represent one of the most critical innovations in modern manufacturing. These machines pla...

-

From Manual Loading to Full Automation: The Upgrade of Vertical Injection Molding Production LinesSuzhou LIZHU Machine has long served injection molding industry clients, witnessing and driving the evolution of vertical injection molding production lines from manual loading to ...

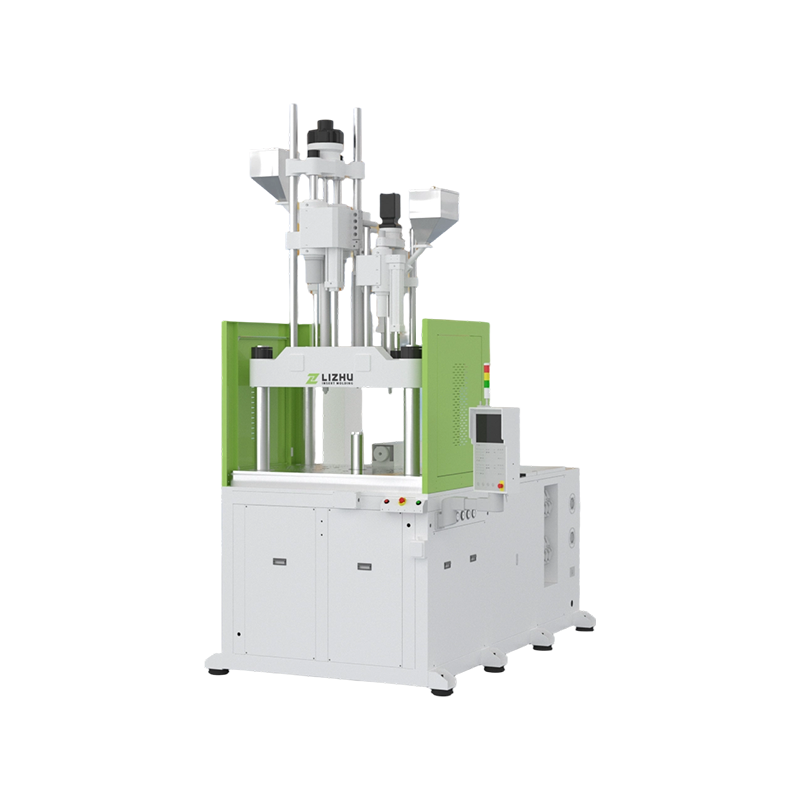

Vertical Hydraulic Press category encompasses machines designed to deliver high precision and efficiency in industrial applications. These presses use hydraulic force to shape or form materials, typically through a controlled vertical movement. They are widely employed in industries like automotive, aerospace, electronics, medical devices, and more, offering versatility in material molding and component shaping.

The Vertical Hydraulic Press series from LIZHU Machinery Co., Ltd. integrates advanced engineering principles, focusing on consistent, high-quality performance. These machines are optimized for applications requiring precise control of pressure, temperature, and timing during the molding process. The vertical orientation allows for easier material loading and removal, maximizing space efficiency in production lines.

Core Features:

-

Precision and Efficiency: With a robust hydraulic system, these presses provide stable and accurate pressure, ensuring uniform results in every cycle.

-

Versatility: Suitable for molding various materials such as plastics, metals, and composites, offering flexibility across diverse industries.

-

Space-Efficient Design: The vertical setup minimizes the required floor space, making them ideal for factories with limited space.

Principle of Operation:

A Vertical Hydraulic Press operates using a hydraulic cylinder that applies force vertically on the material to be molded. The press ensures the material is uniformly shaped under controlled pressure, allowing for the accurate creation of parts. The vertical configuration also enhances the efficiency of material flow and part handling, making the press particularly suitable for high-volume production.

Applications:

-

Automotive Industry: Ideal for producing components like dashboards, door panels, and various automotive parts.

-

Electronics: Used in molding precision parts for electronic devices, such as connectors, switches, and housings.

-

Aerospace: Enables the production of critical parts requiring high precision and strength, including structural components.

-

Medical: Molds specialized components used in medical devices and equipment, ensuring quality and safety.

Comparison with Other Equipment:

Compared to horizontal hydraulic presses, vertical presses are better suited for applications that require minimal floor space and efficient material handling. The vertical configuration is particularly advantageous when dealing with smaller, more intricate parts that require precision molding. Additionally, vertical presses often have faster cycle times due to their ergonomic design, which facilitates quicker material loading and unloading.

Maintenance Tips:

-

Regular Fluid Checks: Hydraulic fluid levels should be monitored regularly to ensure optimal pressure and performance.

-

Preventive Lubrication: Lubricate moving parts such as the press ram and pistons to prevent wear and tear.

-

Cleanliness: Keep the press clean to prevent any debris or contaminants from affecting the molding process and part quality.

-

Routine Inspections: Perform periodic checks on the hydraulic system and electrical components to ensure the press is functioning properly.

By integrating these guidelines, users can extend the operational lifespan of their Vertical Hydraulic Press while maintaining peak performance.

FAQ:

-

What materials can be molded with a Vertical Hydraulic Press?

A Vertical Hydraulic Press is capable of molding a wide variety of materials, including plastics, metals, and composites, making it versatile for different industries. -

How does the vertical configuration improve efficiency?

The vertical orientation reduces the need for excessive floor space and streamlines material loading and unloading, enhancing overall production efficiency. -

What industries use Vertical Hydraulic Presses?

They are primarily used in automotive, electronics, aerospace, and medical industries, where precision molding is required for high-quality components.

中文简体

中文简体