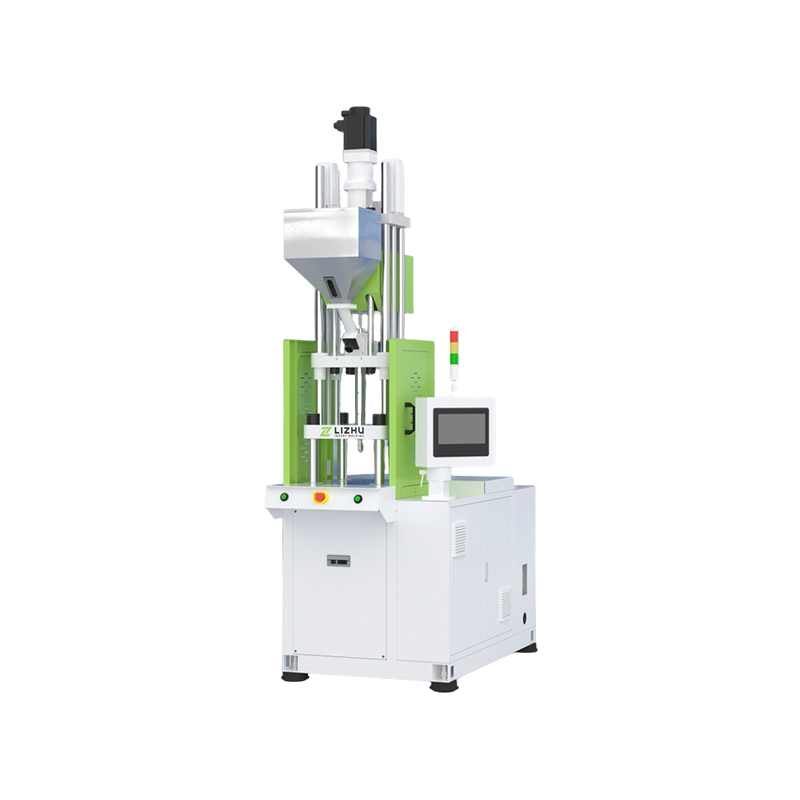

Electric vertical injection molding machine Manufacturers

Series Features:

Low energy consumption, ultra-silent, high precision

The injection and storage system is driven by high-performance servo motor, with efficient closed-loop control, stable repetition accuracy, greatly improving product yield

This machine can add a high-speed injection system, with an injection speed of 500mm/s, and is suitable for thin-wall molding products such as mobile phone connectors and other thin-wall molding products

Scope of application: LCP connectors, precision connectors, products that need to be produced in dust-free workshops.

Product injection weight range: 0.1-150g

Mode locking force: from 40T-160T according to demand

-

What Makes Sliding Vertical Injection Molding Machines Stand Out in Precision and Speed?Introduction to Sliding Vertical Injection Molding Machines As manufacturing processes continue to evolve, the demand for more efficient, precise, and versatile machinery has led t...

-

Why Should You Choose a Vertical Injection Molding Machine for Your Production?Introduction to Vertical Injection Molding Machines A vertical injection molding machine is an advanced manufacturing tool used to create plastic components by injecting molten pla...

-

Why Are Precision Injection Molding Machines Essential for Modern Manufacturing?Introduction to Precision Injection Molding Machines Precision injection molding machines represent one of the most critical innovations in modern manufacturing. These machines pla...

-

From Manual Loading to Full Automation: The Upgrade of Vertical Injection Molding Production LinesSuzhou LIZHU Machine has long served injection molding industry clients, witnessing and driving the evolution of vertical injection molding production lines from manual loading to ...

Electric vertical injection molding machines are specialized equipment designed for high-precision, high-speed injection molding, particularly for applications in the electronics, automotive, medical, aerospace, and semiconductor industries. These machines are characterized by their unique vertical orientation, which allows for better space utilization and enhanced molding efficiency. Typically employed for molding plastics, silicone, BMC, and even metallurgical powders, electric vertical injection molding machines offer superior accuracy, repeatability, and energy efficiency, making them essential for industries that require high-quality, consistent results.

One of the core features of electric vertical injection molding machines is their advanced electric drive system, which ensures precise control of injection pressure, speed, and position. This contrasts with traditional hydraulic systems, offering not only improved energy consumption but also quieter and cleaner operation. The electric system also allows for better control over the molding process, resulting in higher-quality products with fewer defects and reduced scrap rates.

The applications of these machines are vast. In the automotive sector, they are used to mold small, intricate parts such as connectors and sensor housings. In the medical field, electric vertical injection molding machines are used to manufacture parts like syringes, medical connectors, and precision components that require strict hygiene standards. The aerospace industry also benefits from these machines, especially in the production of lightweight, high-performance components.

Product Highlights:

-

High Precision & Accuracy: Electric vertical injection molding machines offer exceptional precision, making them ideal for manufacturing parts with intricate geometries and tight tolerances.

-

Energy Efficiency: These machines utilize electric drives, significantly reducing energy consumption compared to traditional hydraulic systems.

-

Space-Saving Design: The vertical configuration of these machines optimizes floor space, making them ideal for facilities with limited room.

-

Reduced Maintenance: With fewer moving parts, electric vertical injection molding machines require less maintenance, contributing to lower operating costs over time.

Comparison with Other Systems:

When compared to horizontal injection molding machines, electric vertical injection molding machines offer several distinct advantages, especially in terms of energy efficiency and space optimization. The vertical design not only saves space but also allows for easier access to the molding area, making it suitable for automated production lines. Furthermore, the electric control system provides more precise and consistent control of molding parameters, leading to better product quality.

In contrast to hydraulic systems, electric vertical injection molding machines are quieter, cleaner, and more energy-efficient. While hydraulic systems can provide high force for molding large parts, electric machines excel in molding smaller, highly detailed components with high accuracy.

FAQs:

Q: What materials can be molded using electric vertical injection molding machines?

A: These machines can handle a wide range of materials, including plastics, silicone, BMC, and metallurgical powders. The versatility in materials makes them suitable for various applications across different industries.

Q: How do electric vertical injection molding machines contribute to energy savings?

A: By utilizing electric drives, these machines reduce energy consumption compared to traditional hydraulic machines. The precise control of injection speed and pressure further reduces waste and energy use, contributing to overall cost savings.

Q: What are the key benefits of using electric vertical injection molding machines for automotive parts production?

A: Electric vertical injection molding machines are ideal for producing small, precise components, such as sensor housings and connectors. Their accuracy, energy efficiency, and ability to handle complex geometries make them the perfect choice for high-performance automotive parts.

Maintenance Tips:

To ensure optimal performance and longevity of electric vertical injection molding machines, regular maintenance is essential. Key maintenance practices include:

-

Regular Cleaning: Keep the molding area clean to prevent contamination of materials and ensure smooth operation.

-

Inspection of Electrical Components: Regularly check the electric drive system for wear and tear and ensure that electrical connections are secure.

-

Lubrication: Lubricate moving parts periodically to reduce friction and prevent excessive wear.

By following these maintenance guidelines, users can extend the life of their electric vertical injection molding machines and maintain their high performance over time.

中文简体

中文简体