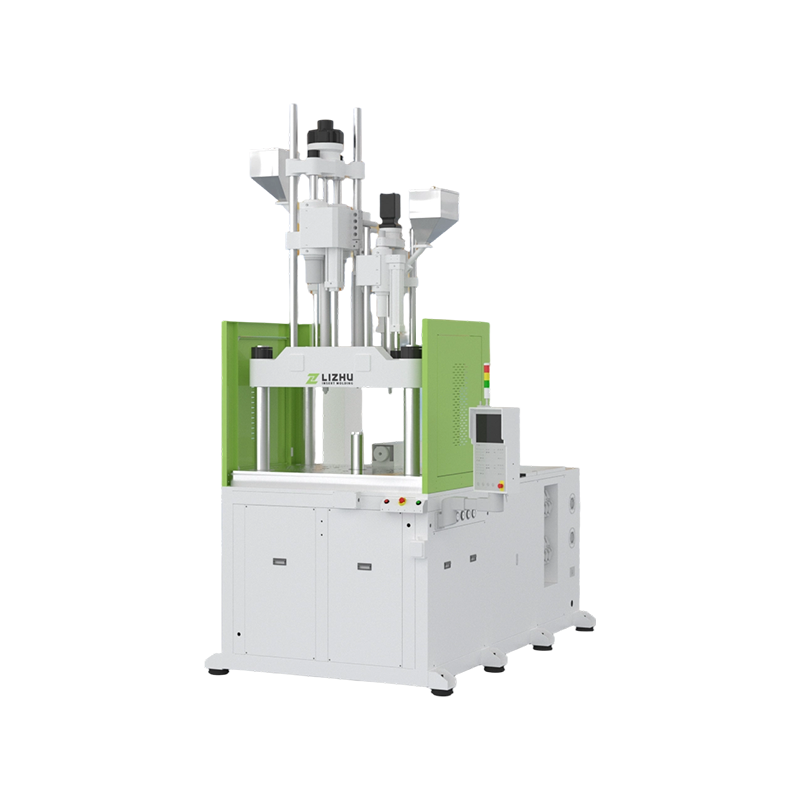

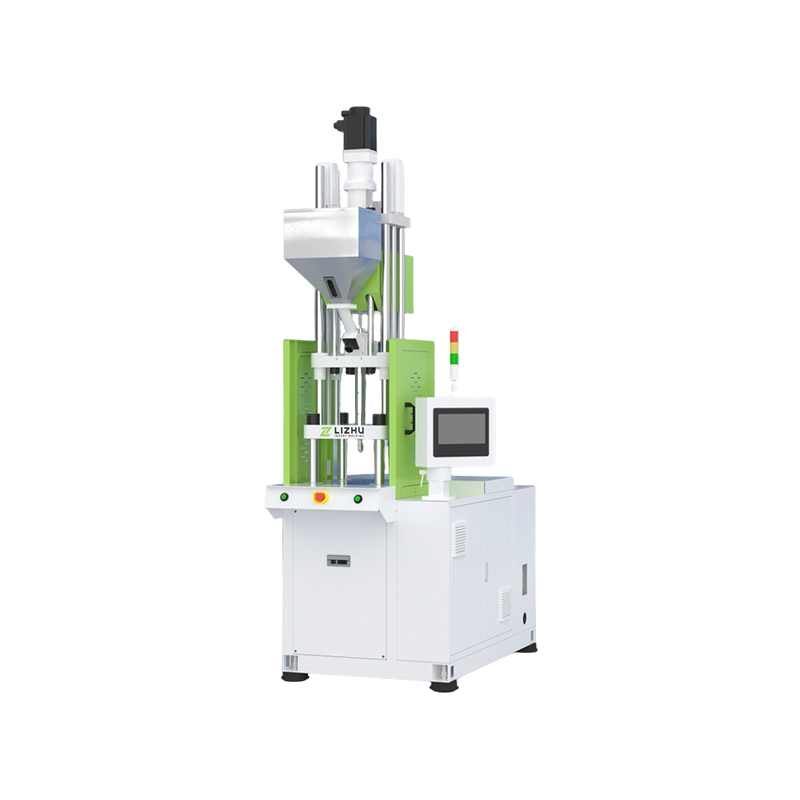

Customized vertical injection molding machine Manufacturers

Different clamping forces and injection mechanisms can be customized according to customer product requirements and can be freely matched

-

What Makes Sliding Vertical Injection Molding Machines Stand Out in Precision and Speed?Introduction to Sliding Vertical Injection Molding Machines As manufacturing processes continue to evolve, the demand for more efficient, precise, and versatile machinery has led t...

-

Why Should You Choose a Vertical Injection Molding Machine for Your Production?Introduction to Vertical Injection Molding Machines A vertical injection molding machine is an advanced manufacturing tool used to create plastic components by injecting molten pla...

-

Why Are Precision Injection Molding Machines Essential for Modern Manufacturing?Introduction to Precision Injection Molding Machines Precision injection molding machines represent one of the most critical innovations in modern manufacturing. These machines pla...

-

From Manual Loading to Full Automation: The Upgrade of Vertical Injection Molding Production LinesSuzhou LIZHU Machine has long served injection molding industry clients, witnessing and driving the evolution of vertical injection molding production lines from manual loading to ...

customized vertical injection molding machine represents a significant advancement in precision manufacturing, tailored to meet the diverse needs of industries like electronics, automotive, medical, and aerospace. These machines are designed to deliver high-speed and high-precision molding processes, offering flexibility and adaptability to specific production requirements.

Core Features and Benefits

-

High-Speed Precision: Customized vertical injection molding machines are engineered for rapid production cycles, ensuring quick turnaround times for various industries.

-

Flexibility in Material Handling: Capable of molding plastics, silicone, BMC, and metallurgical powders with precision, allowing for a wide array of applications.

-

Space-Efficient Design: With their vertical configuration, these machines are ideal for facilities with limited floor space, without sacrificing performance.

-

Customization: Manufacturers can adjust machine settings to meet specific requirements, enhancing process efficiency and product quality.

-

Advanced Features: Options such as sliding tables, rotary tables, and multi-color molding make these machines suitable for producing complex, multi-material parts.

How It Works

The customized vertical injection molding machine operates using the same basic principles as traditional horizontal molding machines but with a vertical orientation. This allows gravity to assist in the material flow, improving cycle time and efficiency. Molten material is injected into the mold cavity, and after cooling, the mold opens to eject the finished product.

Applications and Use Cases

-

Electronics: Producing precision parts such as connectors, housings, and other components.

-

Automotive Industry: Creating various automotive components, from interior trim to exterior body parts.

-

Medical Devices: Used for producing intricate medical components with high precision, such as syringe bodies or valves.

-

Semiconductor Packaging: Essential for molding parts with intricate details required in semiconductor devices.

Why Choose LIZHU's Customized Vertical Injection Molding Machines?

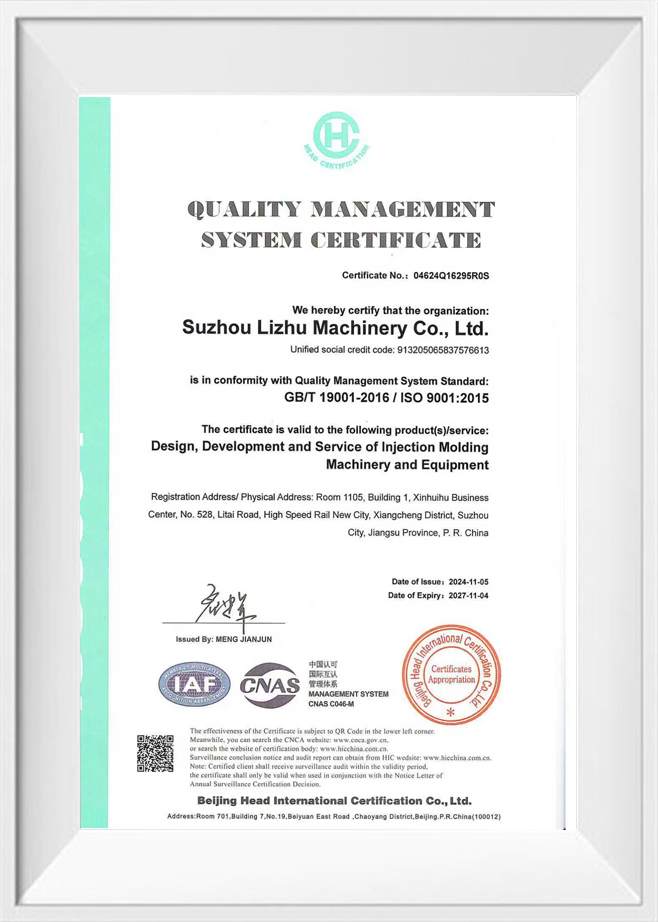

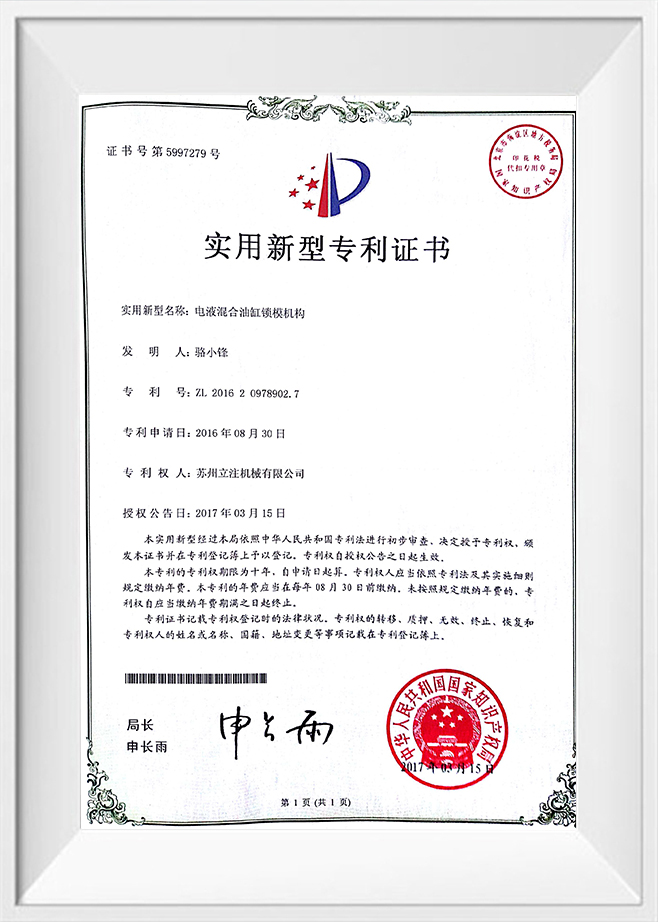

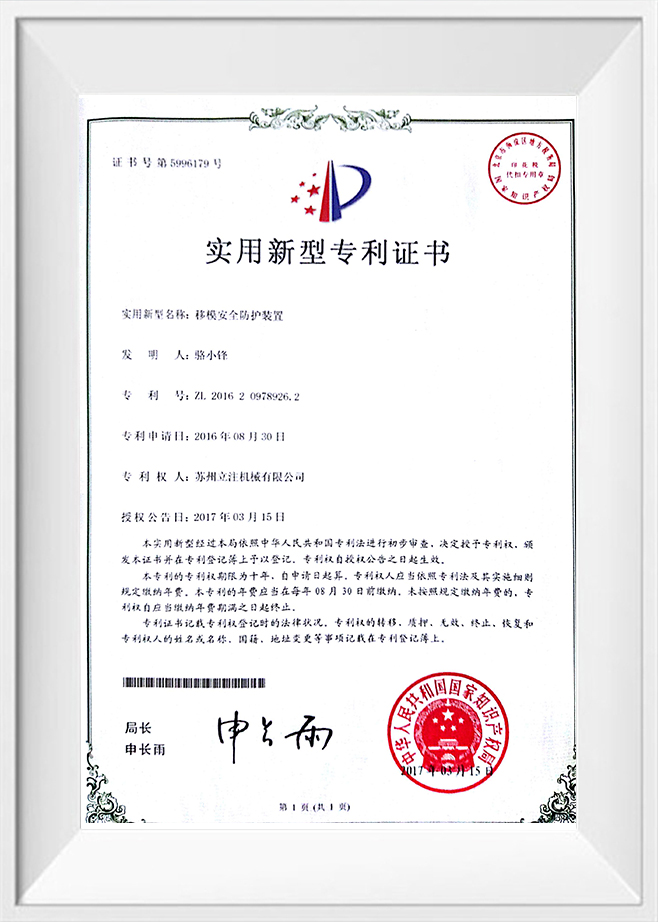

At LIZHU Machinery Co., Ltd., our machines are designed with advanced technology to optimize production efficiency. With years of expertise in the industry, we specialize in customizing vertical injection molding solutions for a variety of applications, backed by our commitment to quality and precision. Our machines are recognized for their exceptional molding accuracy, versatility, and ability to meet international standards, including TUV, CE, and UL certifications.

Comparison with Other Machines

Compared to horizontal injection molding machines, customized vertical injection molding machines offer key advantages:

-

Compact Design: Ideal for environments with limited space, reducing the need for extensive floor layouts.

-

Lower Operating Costs: Vertical machines are typically more cost-effective due to simpler designs and reduced maintenance requirements.

-

Efficient Material Flow: Gravity aids in material flow during injection, leading to shorter cycle times and higher efficiency.

Maintenance Guidelines

-

Regular Inspections: Check components regularly to ensure smooth and consistent operation, especially the injection unit.

-

Lubrication: Proper lubrication of moving parts is essential to minimize wear and ensure optimal machine performance.

-

Cleaning: Routine cleaning of the injection and molding areas helps to prevent material build-up, keeping the production process smooth.

-

Calibration: Ensure periodic calibration to maintain molding accuracy and consistency over time.

Frequently Asked Questions (FAQs)

1. What types of materials can be molded with a customized vertical injection molding machine?

These machines can handle various materials including plastics, silicone, BMC, and metallurgical powders.

2. How does a vertical injection molding machine differ from a horizontal one?

Vertical machines take up less space and utilize gravity to assist with material flow, resulting in quicker cycle times and more cost-efficient operation.

3. What industries benefit most from customized vertical injection molding machines?

Industries such as electronics, automotive, medical devices, and semiconductor packaging benefit from the precision and adaptability of these machines.

4. How can I ensure the optimal performance of my vertical injection molding machine?

Regular maintenance practices such as cleaning, lubrication, and calibration are key to maintaining the high performance and longevity of the machine.

中文简体

中文简体