Precision Injection Molding Machine Manufacturers

-

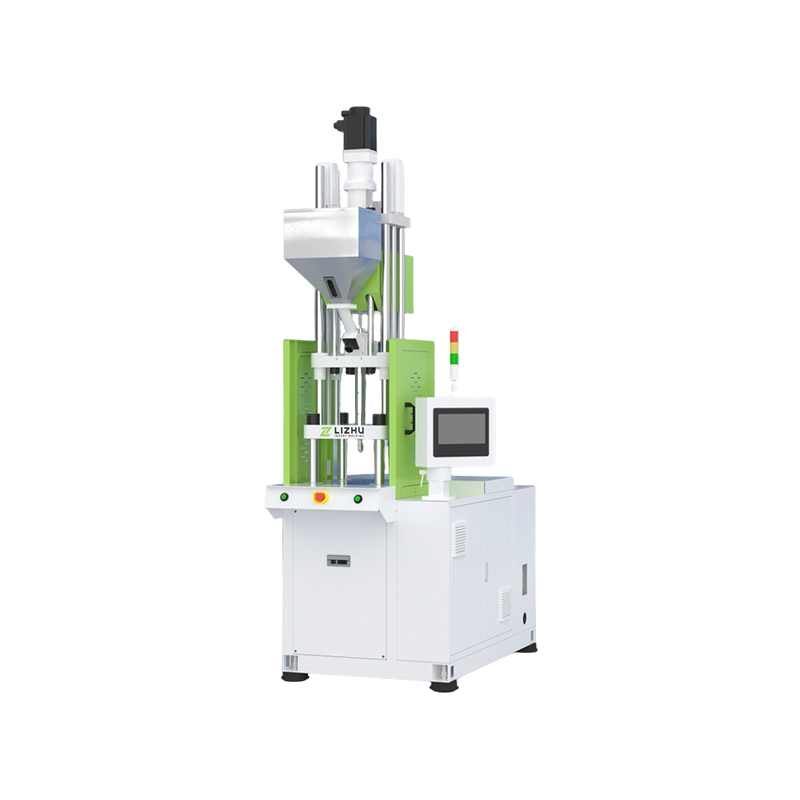

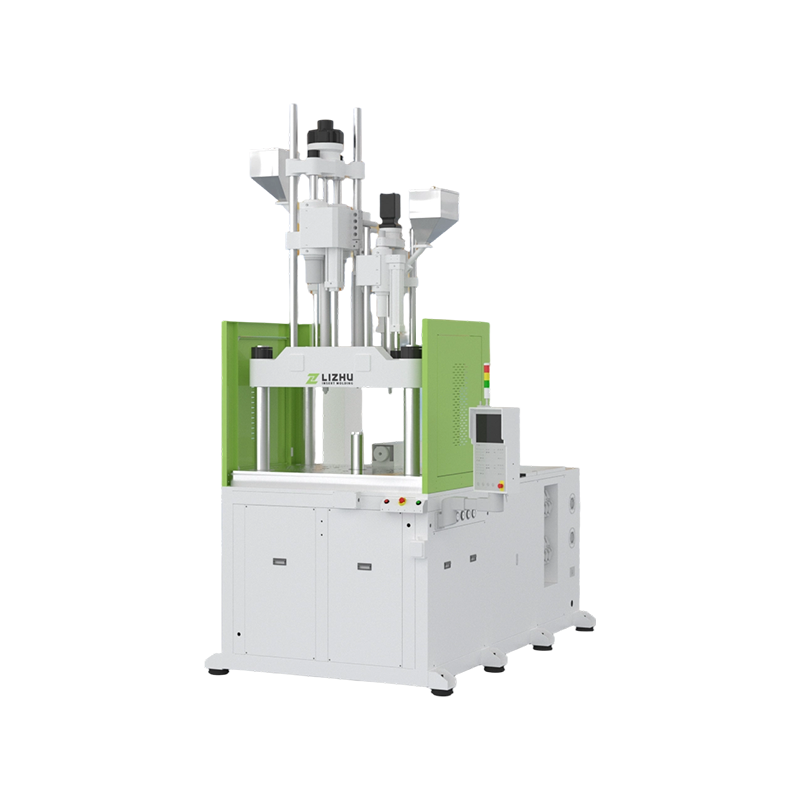

Standard vertical injection molding machine

-

Single Sliding vertical injection molding machine

-

Double Sliding vertical injection molding machine

-

Rotary Table vertical injection molding machine

-

Electric vertical injection molding machine

-

Multicolor vertical injection molding machine

-

Vertical horizontal injection molding machine

-

Customized large size low base vertical injection molding machine

-

Cold Pressing Molding Machine

-

Hot Pressing Molding Machine

-

Automotive Exterior Molding Machine

-

What Makes Sliding Vertical Injection Molding Machines Stand Out in Precision and Speed?Introduction to Sliding Vertical Injection Molding Machines As manufacturing processes continue to evolve, the demand for more efficient, precise, and versatile machinery has led t...

-

Why Should You Choose a Vertical Injection Molding Machine for Your Production?Introduction to Vertical Injection Molding Machines A vertical injection molding machine is an advanced manufacturing tool used to create plastic components by injecting molten pla...

-

Why Are Precision Injection Molding Machines Essential for Modern Manufacturing?Introduction to Precision Injection Molding Machines Precision injection molding machines represent one of the most critical innovations in modern manufacturing. These machines pla...

-

From Manual Loading to Full Automation: The Upgrade of Vertical Injection Molding Production LinesSuzhou LIZHU Machine has long served injection molding industry clients, witnessing and driving the evolution of vertical injection molding production lines from manual loading to ...

Precision Injection Molding Machines are essential for industries that require high-accuracy molding processes. These machines are engineered to deliver consistent, high-quality results, particularly for industries such as automotive, electronics, aerospace, medical devices, and semiconductor packaging. With their ability to mold a variety of materials, including plastics, silicone, BMC (bulk molding compound), and metallurgical powders, precision injection molding machines ensure the production of intricate and durable parts that meet stringent industry standards.

These machines feature cutting-edge technology designed for high-speed operation, energy efficiency, and precision control. The core performance of Precision Injection Molding Machines lies in their ability to maintain tight tolerances, producing parts that are both complex and consistent. Their flexible design allows for the use of multiple molding techniques, including multi-color molding, rotary tables, and sliding table configurations, making them suitable for a diverse range of applications.

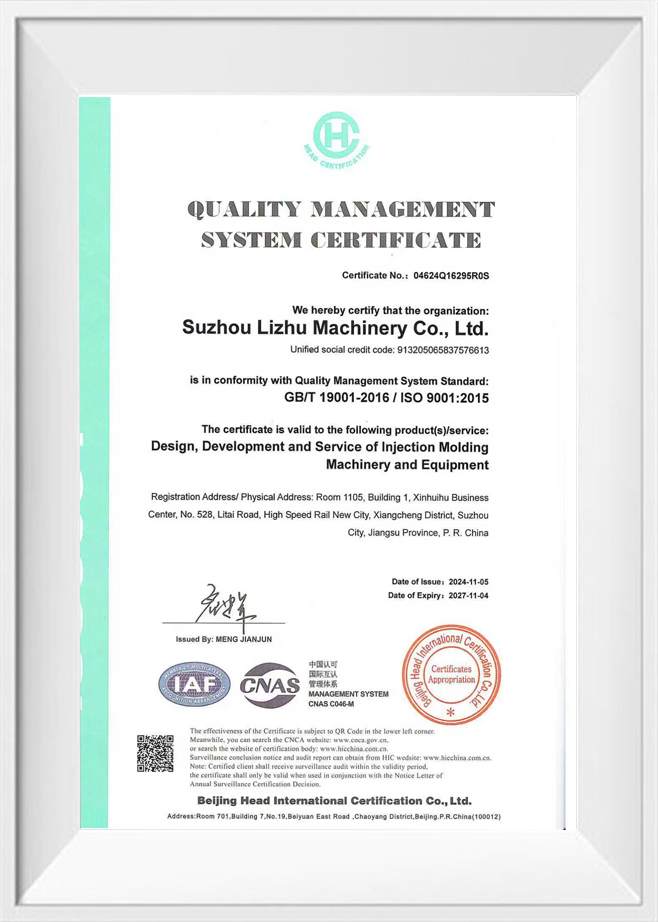

LIZHU Machinery Co., Ltd. specializes in providing Precision Injection Molding Machines that cater to both standard and customized solutions. With a strong presence in over 30 countries, LIZHU is known for its advanced manufacturing techniques and commitment to delivering machines with superior accuracy and longevity.

Key Features:

-

High-Speed Precision: Fast cycle times ensure high productivity and efficiency in manufacturing.

-

Versatility: Capable of handling a variety of materials, from plastics to complex metallurgical powders.

-

Energy-Efficient: Advanced technology reduces power consumption while maintaining performance.

-

Advanced Control Systems: Tight control over injection pressure, temperature, and other critical parameters ensures part quality.

Applications and Case Studies:

-

Automotive Industry: Used to create high-precision parts like connectors, gears, and valve components, ensuring automotive safety and efficiency.

-

Medical Devices: Molds components with strict requirements for hygiene and safety, such as syringes and connectors.

-

Electronics and Aerospace: Molds delicate and high-performance components such as housings, sensors, and connectors that demand extreme precision.

Principles of Operation:

Precision Injection Molding Machines operate by injecting molten material into a mold cavity under high pressure, allowing the material to cool and solidify into the desired shape. The precision comes from the machine's ability to control parameters like injection speed, temperature, and pressure with extreme accuracy.

Comparison with Other Machines:

When compared to traditional injection molding machines, Precision Injection Molding Machines offer greater precision, faster cycle times, and higher flexibility for intricate designs. They are particularly beneficial in industries that demand high-quality parts, such as the electronics and automotive sectors, where small tolerances can make a significant impact on performance.

Maintenance Guidance:

-

Routine Cleaning: Regular cleaning of the injection unit and mold cavities ensures optimal performance and longevity.

-

Lubrication: Proper lubrication of mechanical parts minimizes wear and tear, improving machine efficiency.

-

Calibration: Frequent calibration of sensors and control systems ensures that the machine maintains precise operation standards.

By investing in Precision Injection Molding Machines from LIZHU Machinery, companies can enhance their manufacturing processes with cutting-edge technology that guarantees high quality and productivity.

FAQs:

-

What are the key benefits of using precision injection molding machines?

Precision injection molding machines offer high speed, energy efficiency, and the ability to mold complex parts with tight tolerances, making them ideal for industries requiring high accuracy. -

Can LIZHU's machines be customized for specific applications?

Yes, LIZHU offers both standard and custom solutions to meet specific industry needs, including options for multi-color molding and specialized material molding. -

What maintenance is required for these machines?

Regular cleaning, lubrication, and calibration are essential to ensure that the machine operates at peak efficiency.

By offering a blend of advanced engineering, energy efficiency, and precision, Precision Injection Molding Machines from LIZHU Machinery Co., Ltd. help industries achieve optimal production results while ensuring consistent quality across all applications.

中文简体

中文简体