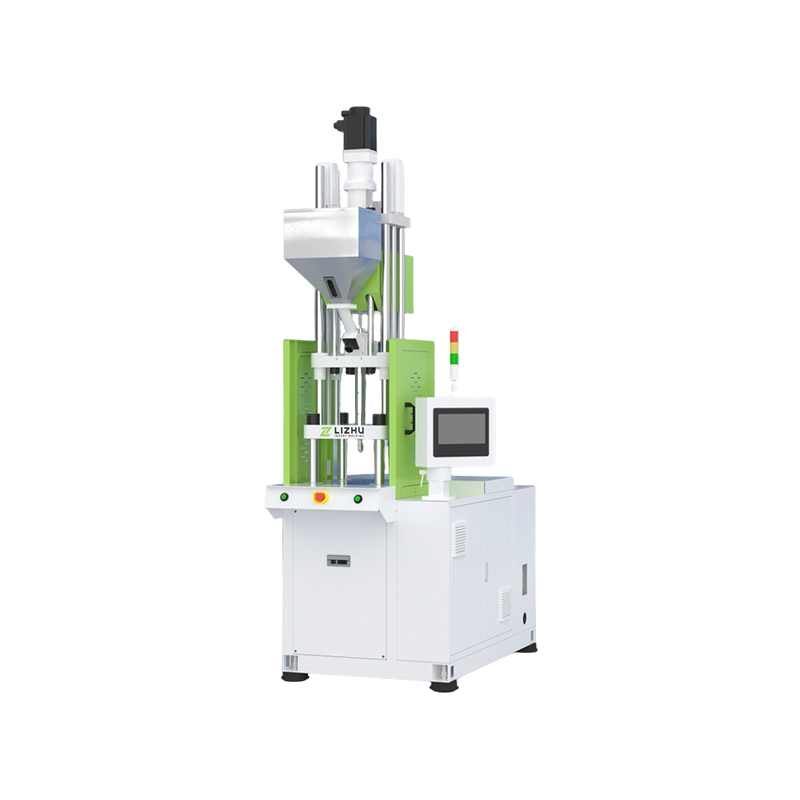

Why do the medical and 3C industries favor vertical electric injection molding machines?

2025-10-10

Vertical electric injection molding machines are highly favored in the medical and 3C industries, mainly due to their accurate matching of technical characteristics and industry demands. The following is a specific analysis of the reasons:

1. High precision and stability

Medical industry: Medical devices (such as syringes, catheter fittings, and precision infusion components) require high dimensional accuracy and surface smoothness, and tolerances often need to be controlled at the micrometer level. The electric injection molding machine adopts servo motor control, which is more accurate than traditional hydraulic presses and can achieve a repeatability accuracy of ± 0.01mm, avoiding burrs or dimensional deviations.

3C industry: The structure of components such as mobile phone lens modules, miniature connectors, and headphone housings is complex. The closed-loop control system of the electric motor can accurately regulate the injection speed and pressure, ensuring product consistency and reducing subsequent processing costs.

2. Clean and environmentally friendly, in compliance with industry standards

Medical compliance: Hydraulic presses may contaminate clean workshops due to oil leakage, while electric injection molding machines do not require hydraulic oil to avoid contamination risks and comply with GMP (Good Manufacturing Practice) and ISO 13485 medical device certification requirements.

3C environmental protection requirements: Electric injection molding machines are free of oil mist and noise, suitable for high cleanliness electronic workshops (such as chip packaging), and meet environmental standards such as RoHS.

3. Effectively save energy and reduce production costs

Energy consumption advantage: The electric motor only consumes power during operation, with standby power consumption close to zero, saving 50% to 70% energy compared to hydraulic presses. For large-scale production in the medical and 3C industries, such as disposable medical consumables and mobile phone cases, long-term costs are significantly reduced.

Quick response: The electric drive has a fast start stop speed, reducing the molding cycle by 10% to 30%, suitable for the fast iteration and short delivery cycle of 3C products.

4. Flexibly adapt to complex processes

Multi component injection molding: The vertical structure is convenient for embedding metal parts or secondary molding, suitable for needle assembly in the medical field and 3C metal plastic composite components (such as Type-C interfaces).

Micro processing: Electric injection molding machines are adept at handling micro injections (with a glue volume of less than 0.1g), meeting the needs of micro sensors and medical microfluidic chips in the 3C industry.

5. Convenient automation integration

Medical automation: The vertical design is easy to integrate with robotic arms and visual inspection systems, achieving fully automated production in sterile environments (such as pre filled syringes).

3C high efficiency: With the cooperation of robots, in mold labeling (IML), fine embedding and other processes can be achieved, improving the production efficiency of products such as mobile phone covers.

6. Low maintenance and long lifespan

The electric structure eliminates the need for regular replacement of hydraulic oil and maintenance of the oil circuit, resulting in a lower failure rate. It is suitable for continuous production in the medical and 3C industries, and has a higher overall equipment utilization rate (OEE).

summary

Vertical electric injection molding machines have become the choice for fine and miniaturized production in the medical and 3C industries due to their advantages of high precision, cleanliness, energy saving, and flexible integration. With the continuous improvement of product quality and automation requirements in the industry, the application of electric injection molding machines will further expand.

News categories

Product categories

Exhibition Information

-

How to choose high cost-effective standard vertical injection molding machines?

Oct 10,2025 -

Key points for maintenance and upkeep of the mechanical part of the vertical injection molding machine

Oct 10,2025 -

Why do the medical and 3C industries favor vertical electric injection molding machines?

Oct 10,2025

中文简体

中文简体