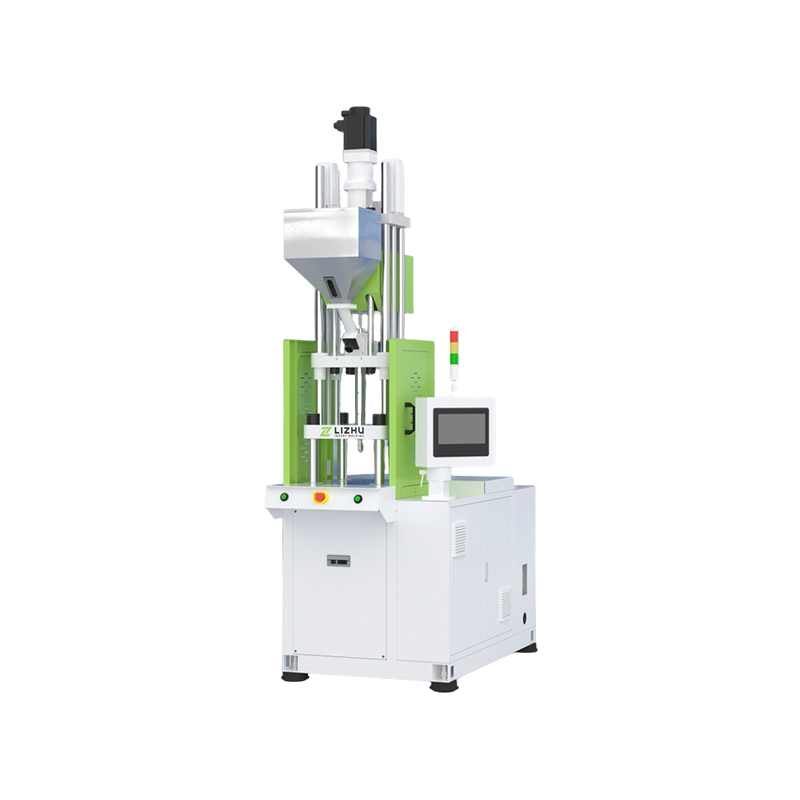

How to choose high cost-effective standard vertical injection molding machines?

2025-10-10

Clarify production requirements:

Product information: Determine the type, size, weight, and precision requirements of the product to be produced. When producing small and fine electronic components, it is necessary to choose injection molding machines with high precision and moderate clamping force; When producing larger plastic containers, it is necessary to consider models with high clamping force and large injection volume.

Plastic types: Different plastics have different molding processes. When producing engineering plastics such as PC and PA, it is necessary to select injection molding machines with a high screw compression ratio and high injection pressure. The production of general plastics such as PE and PP requires relatively low requirements for injection molding machines.

Production requirement: Based on the enterprise's production plan, estimate the future production volume. Enterprises with high production capacity can choose high-speed, multi-loop injection molding machines to improve production efficiency; Enterprises with small output can choose ordinary models to reduce equipment costs.

Consider device performance:

Locking force: determined by the projected area of the product in the direction of the switch mold, the number of mold holes, and the pressure inside the mold. After calculating the supporting force, the machine locking force needs to be greater than the supporting force, and for safety reasons, it usually needs to be greater than 1.17 times the supporting force.

Injection volume: determined based on the weight of the finished product and the number of mold holes. To ensure stability, the injection volume must be at least 1.35 times the weight of the finished product, that is, the weight of the finished product must be within 75% of the injection volume.

Screw diameter: It is necessary to comprehensively consider the injection volume, injection pressure, and injection speed. Smaller diameter screws can provide higher injection pressure but lower firing rate; A screw with a larger diameter has a larger injection volume, but the injection pressure may be lower.

Opening and closing speed: A fast opening and closing speed can shorten the molding cycle and improve production efficiency. For thin-walled products or products with large production batches, fast mold opening and closing speed is particularly important.

Control accuracy: With high-precision temperature, pressure, and speed control, it can ensure the stability of product quality. If an injection molding machine adopts a closed-loop control system, it can more accurately control the injection molding process.

Assessing equipment quality:

Brand and reputation: Choose a well-known and reputable brand, and you can learn about the brand's reputation and user reviews through online platforms, industry forums, and peer advice. Brands such as Haitian and Bochuang have a high level of popularity and good reputation in the market.

Manufacturing process: Observe the appearance process of the equipment, such as whether the welding of the body is firm and whether the surface treatment is smooth; Understand the internal structure of the equipment, such as the machining accuracy of screws and barrels, and the stability of the clamping mechanism.

Key components: Understand the brand and quality of key components such as screws, barrels, oil pumps, motors, etc. Excellent key components can improve the performance and service life of equipment, and reduce maintenance costs.

Pay attention to after-sales service:

Technical support: Suppliers should have a professional technical team that can provide timely technical support to enterprises, such as equipment debugging, troubleshooting, process optimization, etc.

Accessory supply: Ensure that suppliers can provide original equipment accessories in a timely manner, shorten equipment maintenance time, and reduce downtime losses.

Training services: Suppliers should provide equipment operation and maintenance training to enable enterprise employees to proficiently master equipment operation and daily maintenance skills.

Evaluate prices and costs:

Equipment price: On the premise of meeting production needs and quality requirements, compare the prices of different brands and models of injection molding machines, and choose products with high cost-effectiveness. But don't just focus on the price and overlook the performance and quality of the equipment.

Operating costs: Consider operating costs such as equipment energy consumption, raw material utilization, and labor costs. Although the purchase price of energy-saving injection molding machines may be higher, long-term use can reduce energy consumption costs.

Maintenance cost: Understand the maintenance requirements and repair costs of the equipment, including the frequency and price of replacing vulnerable parts, and the charging standards for repair services.

Consider scalability:

Future product changes: Enterprises' products may be constantly updated or new varieties may be added. The selected injection molding machines should be scalable and adaptable to future product changes.

Production scale expansion: If the enterprise has plans to expand production scale, it can choose injection molding machines with upgrade space, such as increasing the number of mold cavities, improving mold locking force or injection volume, etc.

News categories

Product categories

Exhibition Information

-

How to choose high cost-effective standard vertical injection molding machines?

Oct 10,2025 -

Key points for maintenance and upkeep of the mechanical part of the vertical injection molding machine

Oct 10,2025 -

Why do the medical and 3C industries favor vertical electric injection molding machines?

Oct 10,2025

中文简体

中文简体