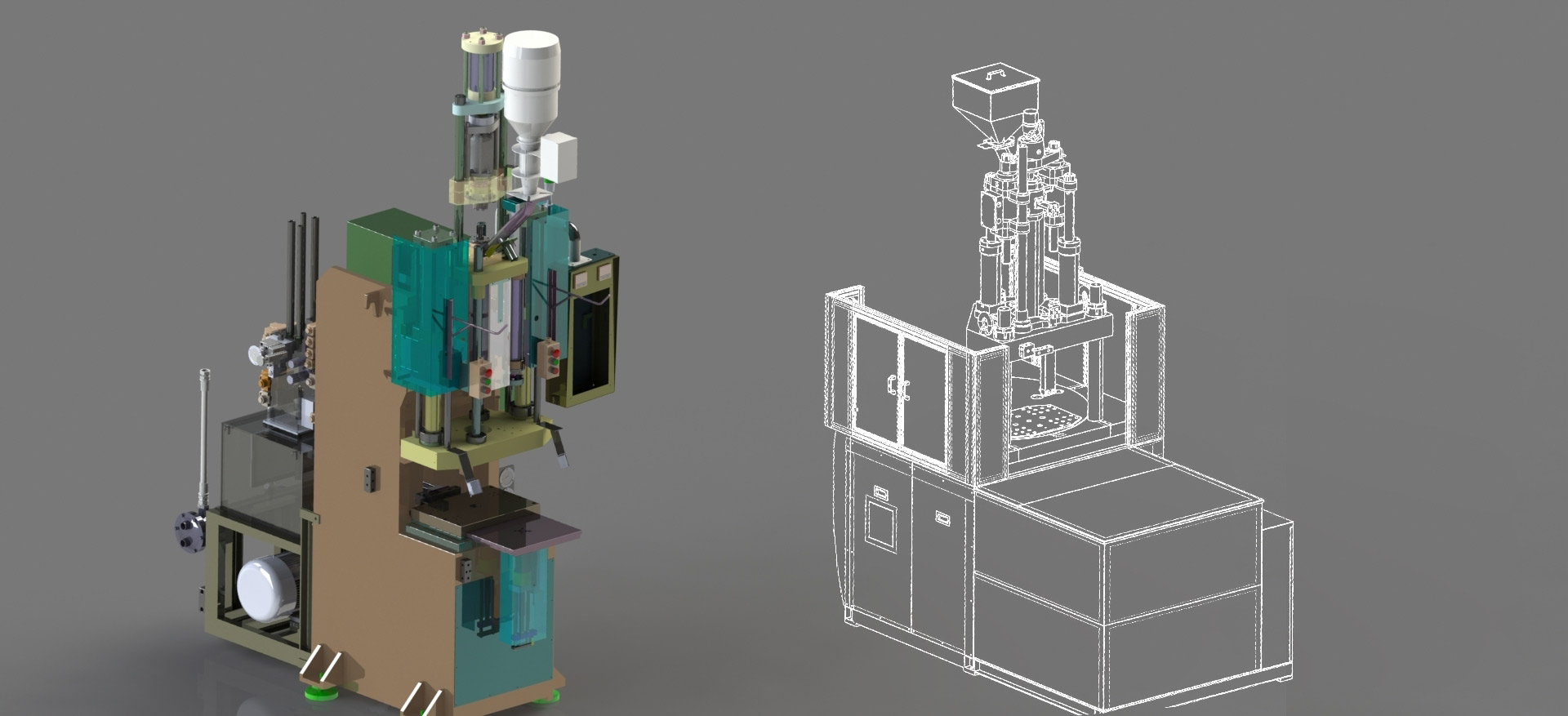

Lizhu Machinery has modern research and development centers in Suzhou and Wuhu, equipped with advanced experimental equipment and testing platforms.

The center focuses on the cutting-edge technology development of vertical injection molding machines, covering core areas such as servo drive, energy-saving systems, and automation integration. Through strict R&D processes and standardized testing, we ensure that each device meets international requirements and the precision molding needs of different industries.

中文简体

中文简体